HOME

/

How To Use Electric Tape?

How To Use Electric Tape?

What is a electrical tape?

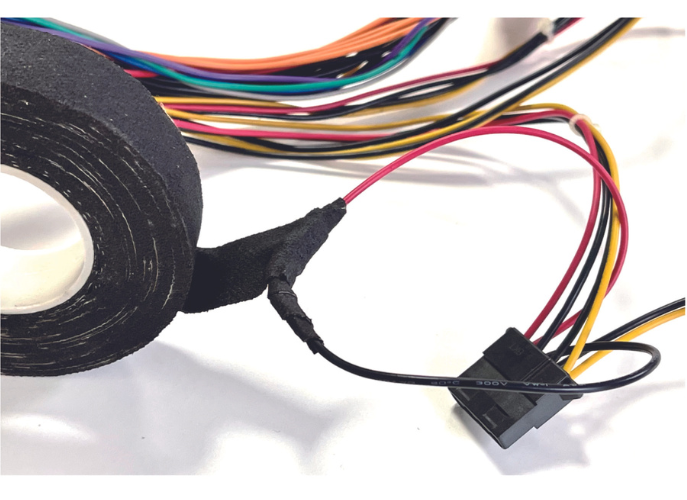

Electrical tape is a type of adhesive tape specifically designed for insulating and protecting electrical wires and connections. It is made of a flexible material, usually vinyl or rubber, that is resistant to heat, moisture, and various chemicals. Electrical tape is typically colored black, but it is also available in other colors for coding purposes. Its primary purpose is to provide insulation to prevent electrical shocks and short circuits by wrapping around exposed wires or connections. Additionally, it can be used for bundling wires together and marking them for identification purposes.

Importance of proper usage for electrical safety

Proper usage of electrical tape is crucial for electrical safety. When used correctly, electrical tape provides insulation to wires and connections, preventing electrical shocks and short circuits. It helps maintain the integrity of electrical systems by protecting them from moisture, heat, and other environmental factors that could cause damage or malfunction. Additionally, proper application of electrical tape ensures secure connections, reducing the risk of exposed wires or loose connections that could lead to fires or other hazards. Therefore, understanding and adhering to best practices for using electrical tape is essential for maintaining a safe and reliable electrical infrastructure.

Materials Needed

To ensure a successful application of electrical tape, it’s essential to gather the necessary materials beforehand. Here’s a breakdown of the materials needed:

1. Electrical tape: This is the primary material required for insulating and securing electrical connections. Electrical tape is specifically designed to provide insulation and protection to wires and connections, safeguarding them against electrical shocks and short circuits. It is made of a flexible material, typically vinyl or rubber, with an adhesive backing that allows it to adhere firmly to surfaces. Electrical tape is available in various widths, colors, and thicknesses to suit different applications and preferences. Before starting any electrical work, it’s crucial to verify that the electrical tape is in good condition, free from tears or damage, to ensure effective insulation and safety.

2. Clean, dry surface: A clean and dry surface is essential for ensuring the proper adhesion and effectiveness of electrical tape. Before applying the tape, it’s important to thoroughly clean the surface where it will be used to remove any dirt, dust, grease, or moisture that could interfere with adhesion. This can be done using a clean, dry cloth or paper towel to wipe down the surface and remove any contaminants. Ensuring the surface is dry is equally important, as moisture can compromise the adhesive properties of the tape and lead to poor insulation or adhesion. By starting with a clean, dry surface, you can maximize the effectiveness of the electrical tape and ensure a secure and reliable electrical connection.

3. Scissors (if needed): While electrical tape can often be torn by hand, scissors may be necessary for cutting precise lengths or shapes, especially when working with thicker or wider tape. Scissors allow for clean and accurate cuts, which can be particularly important when working in tight spaces or when wrapping around small or intricate components. It’s helpful to have a pair of sharp scissors readily available when working with electrical tape to ensure smooth and precise cutting without damaging the tape. However, if tearing the tape by hand is sufficient for the task at hand, scissors may not be needed.

Steps to Use Electric Tape

Here’s a detailed guide on how to use electrical tape effectively:

Step 1: Preparation

* Begin by ensuring that the surface where the electrical tape will be applied is clean and completely dry. This step is crucial for promoting optimal adhesion and ensuring a secure seal.

* If necessary, use scissors to cut the desired length of electrical tape. Cutting the tape to the appropriate size beforehand will help streamline the application process and ensure a neat and tidy finish.

Step 2: Wrapping the Wire

* Start at one end of the wire or the area that needs to be insulated.

* Hold the end of the electrical tape against the wire at a slight angle to initiate the wrapping process.

* Begin wrapping the tape around the wire in a spiral motion, ensuring that each layer overlaps slightly with the previous one. This overlapping technique helps to create a tight seal and provides effective insulation.

* As you wrap, gently pull the tape snugly to ensure a secure fit around the wire. Avoid pulling too tightly, as this could stretch the tape and compromise its effectiveness.

* Continue wrapping until the entire exposed area of the wire is covered with at least two layers of electrical tape. Multiple layers help to enhance the insulation and provide added protection against potential electrical hazards.

Step 3: Securing the End

* Once you have wrapped the wire with the desired number of layers of electrical tape, tear or cut the tape to finish.

* Press the end of the tape firmly against the wire to secure it in place. Ensure that there are no loose ends or gaps in the tape that could compromise the seal.

* Finally, rub the entire wrapped area with your fingers to ensure good adhesion and seal. This step helps to further secure the tape in place and ensure a reliable insulation barrier.

Additional Tips

Here are some additional tips to ensure the effective use of electrical tape:

1. Stretch the tape slightly as you wrap to activate its adhesive properties. When applying electrical tape, gently stretching it as you wrap helps activate the adhesive, ensuring a secure bond with the surface. This activation is crucial for creating a strong seal and enhancing the tape’s ability to provide insulation and protection to the wires or connections.

2. Avoid stretching the tape too much, as it may cause it to lose elasticity. While stretching the tape can improve its adhesive properties, excessive stretching can lead to the tape becoming thin and less resilient. Overstretched tape may not provide adequate insulation or sealing, increasing the risk of electrical hazards. Therefore, it’s important to maintain a moderate level of tension while wrapping to preserve the tape’s elasticity and effectiveness.

3. Overlap each layer of tape by about half its width to ensure complete coverage and insulation. Proper overlap is essential for creating a continuous barrier that prevents moisture, dust, and other contaminants from penetrating the wrapped area. By overlapping each layer of tape, you ensure that there are no gaps or exposed areas where potential hazards could occur. This technique helps maximize the tape’s ability to provide insulation and protection to the wires or connections.

4. Check for any air bubbles or gaps in the tape and smooth them out with your fingers. After wrapping the wires or connections with electrical tape, inspect the surface for any signs of air bubbles or gaps. These imperfections can compromise the effectiveness of the insulation and sealing. Using your fingers, gently press down on the tape to smooth out any bubbles and ensure a secure seal. This final step helps to optimize the performance of the electrical tape and minimize the risk of electrical hazards.

Conclusion

In conclusion, the proper application of electrical tape is paramount for ensuring safety in electrical installations and maintenance. Electrical tape serves as a critical component in insulating wires and connections, guarding against the risks of electrical shocks, short circuits, and fires. By effectively using electrical tape, individuals can significantly reduce the likelihood of accidents and injuries associated with electrical hazards. Therefore, it is essential to understand and adhere to best practices when applying electrical tape to ensure optimal safety in electrical projects.

The key steps for using electrical tape effectively include proper preparation of the surface, wrapping the wire or connection with overlapping layers of tape, and securely sealing the end to prevent unraveling. Additionally, gentle stretching of the tape to activate its adhesive properties, avoiding overstretching, and checking for air bubbles or gaps are important considerations for achieving a reliable insulation barrier. By following these steps diligently, individuals can maximize the effectiveness of electrical tape in providing insulation and protection to wires and connections.

Lastly, for those who may feel uncertain about the proper usage of electrical tape or are dealing with complex electrical work, seeking professional assistance is highly encouraged. Electricians and other qualified professionals possess the knowledge, skills, and experience necessary to ensure the safe and effective application of electrical tape in various electrical projects. They can offer expert guidance, troubleshoot potential issues, and provide valuable insights to ensure the integrity and safety of electrical installations. When in doubt, entrusting electrical tasks to professionals can help mitigate risks and promote peace of mind.