HOME

/

What Are Cable Cleats And How Do Them Work?

What Are Cable Cleats And How Do Them Work?

What is a Cable Cleat?

A cable cleat is a device used to secure and support electrical cables in various installations, particularly in industrial settings. It is typically made of metal, plastic, or composite materials and is designed to prevent cables from moving excessively or becoming damaged due to vibrations, short circuits, or other mechanical stresses.

Cable cleats come in various shapes and sizes depending on the type and size of cables being used. They are installed along the length of the cable route and are usually fixed to a supporting structure such as a cable tray, ladder rack, or directly onto a wall or floor.

The primary function of a cable cleat is to maintain the spacing and arrangement of cables, ensuring they remain organized and secure even during dynamic conditions such as short circuits or seismic events. Additionally, cable cleats help to minimize the risk of electrical faults and maintain the integrity of the electrical installation.

The Purpose of Cable Cleats

Cable cleats serve as vital components in a variety of applications, notably within industries such as electrical power distribution, telecommunications, and manufacturing. Their primary function is to uphold and secure cables, safeguarding them against movement, strain, and potential damage during installation, operation, and in the event of short circuits or faults.

These devices fulfill several key purposes and functions:

Firstly, cable cleats provide essential mechanical support to cables, preventing them from sagging or shifting out of position. This capability helps to maintain the integrity of cable installations and mitigates the risk of damage caused by unsupported cables.

Additionally, cleats aid in the organization and management of cables, ensuring they remain in orderly arrangements. This not only reduces the likelihood of cable entanglement but also simplifies maintenance and inspection procedures.

Safety is another critical aspect addressed by cable cleats. By securely fastening cables in place, they diminish the chances of accidents resulting from loose or dangling cables. In instances of short circuits or faults, cleats play a crucial role in preventing cables from flailing and causing further harm by firmly holding them in position.

Moreover, cable cleats facilitate even distribution of mechanical forces exerted on cables, thereby minimizing stress concentrations and safeguarding both the cables and the surrounding infrastructure. This feature is particularly valuable in environments subject to high mechanical loads, such as industrial settings or areas prone to vibration.

In many industries, regulatory requirements and standards mandate the use of cable cleats to ensure the safe and reliable operation of electrical and communication systems. By adhering to these standards, cleats aid installations in complying with industry regulations pertaining to cable management and safety protocols.

Accordingly, cable cleats play an indispensable role in bolstering the reliability, safety, and longevity of cable installations across diverse industries. By mitigating risks associated with cable movement, strain, and short circuits, they contribute significantly to the efficient and uninterrupted operation of electrical and communication networks.

Types of Cable Cleats

There are several types of cable cleats available, each designed to suit different cable configurations, installation requirements, and environmental conditions. Some common types of cable cleats include:

* Single Cable Cleats: These cleats are designed to support and secure individual cables, providing a simple and effective solution for smaller cable installations.

* Multicore Cable Cleats: Multicore cable cleats are specifically designed to support bundled cables or multicore cable arrangements. They provide additional support and stability to grouped cables, preventing movement and strain.

* Trefoil Cable Cleats: Trefoil cable cleats are designed for three-core cables, arranging them in a triangular configuration. This design helps to maintain separation between the cables and distribute mechanical forces evenly, reducing the risk of damage during short circuits or faults.

* Clamp-Type Cable Cleats: Clamp-type cable cleats feature a clamping mechanism that securely holds cables in place. They are often used in applications where cables are subject to high mechanical loads or vibrations.

* Snap-In Cable Cleats: Snap-in cable cleats offer a quick and easy installation method, allowing cables to be securely snapped into place. They are commonly used in applications where frequent maintenance or reconfiguration of cable installations is required.

* Ladder Cable Cleats: Ladder cable cleats are designed to support cables on cable ladders or trays. They help to maintain the separation and alignment of cables on horizontal cable runs, ensuring proper cable management and reducing the risk of cable damage.

* Vertical Cable Cleats: Vertical cable cleats are used to support cables on vertical cable runs, such as cable risers or cable ducts. They prevent cables from sagging or shifting out of position, ensuring the integrity of the cable installation.

These are just a few examples of the various types of cable cleats available in the market. The choice of cable cleat depends on factors such as the type and size of cables, the installation environment, and the specific requirements of the application. Proper selection and installation of cable cleats are essential to ensure the safe and reliable operation of cable installations.

How do Cable Cleats Work

Cable cleats function by securely fastening cables to a supporting structure, such as a cable tray, ladder, or wall, to prevent movement, strain, and damage. Their operation is relatively straightforward yet crucial for maintaining the integrity and safety of cable installations.

When installed, cable cleats encircle the cables and are typically fastened to the supporting structure using bolts, screws, or other fastening mechanisms. The design of the cleats ensures that they firmly grip the cables, holding them in place even during mechanical stress or short-circuit events.

During normal operation, cable cleats distribute the mechanical forces exerted on the cables evenly, minimizing stress concentrations and preventing excessive movement or strain. This helps to preserve the structural integrity of the cables and the surrounding infrastructure, reducing the risk of damage and downtime.

In the event of a fault, such as a short circuit, cable cleats play a critical role in containing the cables and preventing them from flailing or causing further damage. By securely holding the cables in place, cleats help to mitigate the risks associated with short circuits, such as electrical arcing and cable overheating.

The effectiveness of cable cleats depends on factors such as their design, material composition, and installation method. Proper selection and installation of cable cleats are essential to ensure that they perform their intended function effectively and contribute to the safe and reliable operation of cable installations. Regular inspection and maintenance of cable cleats are also important to identify any signs of wear or damage and address them promptly to prevent potential safety hazards.

Factors to Consider When Choosing Cable Cleats

When selecting cable cleats for a specific application, several factors need to be carefully considered to ensure the effectiveness and reliability of the cable management system.

Firstly, the type and size of the cables being used play a crucial role in determining the appropriate cable cleats. Different types of cables, such as single-core, multicore, or trefoil cables, may require specific cleat designs to provide adequate support and protection.

The environmental conditions in which the cables will be installed are also important considerations. Factors such as temperature extremes, humidity, exposure to chemicals or corrosive substances, and the presence of vibrations or mechanical stress can impact the performance and lifespan of cable cleats. It’s essential to choose cleats made from materials that can withstand these environmental challenges.

Another factor to consider is the mechanical load that the cables will be subjected to during operation. Cable cleats must be able to withstand the forces exerted on the cables, including those caused by short circuits, cable movement, and external impacts. Cleats with higher load-bearing capacities may be required for applications with heavy mechanical loads or vibrations.

The installation method and mounting arrangement also need to be taken into account when choosing cable cleats. Cleats should be compatible with the type of supporting structure, such as cable trays, ladders, walls, or floors, and the method of attachment used. The ease of installation and accessibility for maintenance and inspection should also be considered to ensure the long-term reliability of the cable management system.

Additionally, compliance with industry standards and regulatory requirements is essential when selecting cable cleats. Cleats should meet the relevant safety and performance standards to ensure the safe and reliable operation of the cable installation.

Therefore, careful consideration of these factors is necessary to choose cable cleats that are suitable for the specific requirements of the application and provide effective support, protection, and management of the cables. Collaboration with experienced professionals and adherence to best practices can help ensure the successful implementation of a cable management system that meets the needs of the installation while prioritizing safety and reliability.

Advantages of Using Cable Cleats

Using cable cleats offers several advantages in cable management and installation, making them an essential component in various industries and applications.

One primary advantage of cable cleats is their ability to provide reliable support and protection to cables. By securely fastening cables to supporting structures, such as cable trays or ladders, cleats prevent them from sagging, shifting, or coming into contact with each other. This helps to maintain the integrity of the cable installation and reduces the risk of damage caused by excessive movement or strain.

Additionally, cable cleats enhance safety by minimizing the risk of accidents and hazards associated with loose or dangling cables. In the event of a short circuit or fault, cleats help contain the cables and prevent them from flailing or causing further damage. This is especially important in environments where electrical safety is paramount, such as industrial facilities, power plants, and telecommunications networks.

Another advantage of using cable cleats is their ability to facilitate proper cable management and organization. Cleats help to arrange cables in orderly configurations, reducing the risk of cable entanglement and simplifying maintenance and inspection procedures. This ensures that cables are easily accessible for troubleshooting, repairs, or upgrades, minimizing downtime and optimizing system performance.

Furthermore, cable cleats contribute to the longevity and reliability of cable installations by distributing mechanical forces evenly across the cables. This helps to minimize stress concentrations and prevent damage to the cables and surrounding infrastructure, even in environments prone to vibrations or mechanical loads.

Hence, the advantages of using cable cleats include enhanced cable support and protection, improved safety, simplified cable management, and increased reliability. By investing in high-quality cleats and adhering to best practices in installation and maintenance, organizations can ensure the efficient and uninterrupted operation of their cable systems while prioritizing safety and compliance with industry standards.

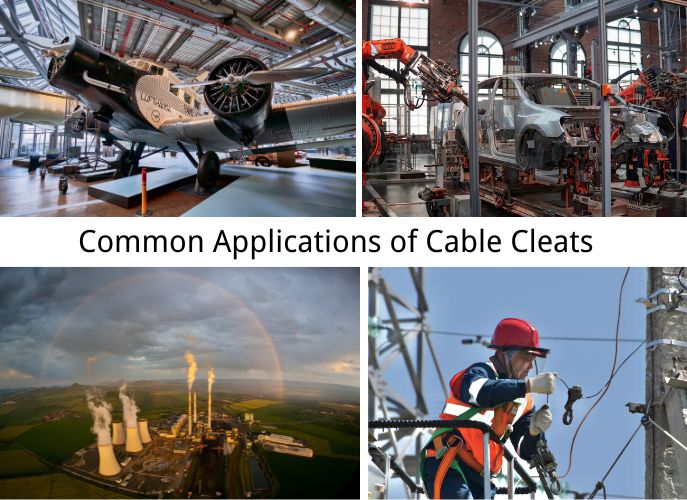

Common Applications of Cable Cleats

Cable cleats are widely used across various industries and applications where the secure fastening and support of cables are necessary. Some common applications include:

* Electrical Power Distribution: Cable cleats are extensively used in electrical power distribution networks, including substations, power plants, and transmission lines. They secure high-voltage cables, preventing movement and damage during normal operation and fault conditions.

* Industrial Facilities: In manufacturing plants, refineries, and industrial facilities, cable cleats are employed to support cables for machinery, equipment, and control systems. They help to minimize the risk of accidents and downtime by preventing cable damage caused by vibrations and mechanical stress.

* Telecommunications Networks: Cable cleats are crucial for organizing and securing cables in telecommunications infrastructure, including data centers, telecommunications towers, and underground cable networks. They ensure the proper alignment and separation of cables, maintaining network performance and reliability.

* Transportation Infrastructure: Cable cleats are used in railways, airports, tunnels, and other transportation facilities to secure cables for lighting, signaling, and control systems. They withstand the mechanical stresses and vibrations associated with moving vehicles, ensuring the continuous operation of critical infrastructure systems.

* Renewable Energy Installations: Wind farms, solar power plants, and other renewable energy installations utilize cable cleats to support cables connecting turbines, inverters, and other components. Cleats withstand environmental conditions and mechanical stresses, ensuring the reliable operation of renewable energy systems.

* Commercial Buildings: Cable cleats are employed in commercial buildings for organizing and securing cables used in electrical distribution, lighting, HVAC systems, and communication networks. They help maintain a tidy cable installation, facilitating maintenance tasks and minimizing the risk of cable damage and accidents.

Overall, cable cleats play a vital role in ensuring the safety, reliability, and efficiency of cable installations across various industries and environments. By selecting the appropriate cleats and adhering to installation best practices, organizations can optimize the performance of their cable systems and minimize the risk of downtime and accidents.

Conclusion

In conclusion, cable cleats are indispensable components in cable management systems across a wide range of industries and applications. Their ability to securely fasten and support cables ensures the safety, reliability, and efficiency of electrical, telecommunications, and control systems. Cable cleats prevent cable movement, strain, and damage, even under harsh environmental conditions or during fault events. By organizing cables and distributing mechanical forces evenly, cleats contribute to the longevity and optimal performance of cable installations.

From electrical power distribution to telecommunications networks, transportation infrastructure, industrial facilities, renewable energy installations, and commercial buildings, cable cleats play a crucial role in maintaining the integrity of cable systems and safeguarding against accidents and downtime. As technology evolves and infrastructure advances, the importance of cable cleats remains paramount, highlighting their enduring significance in modern-day engineering and construction practices.

Dingdong Electrical

Dingdong Electrical is a trusted supplier specializing in providing professional-grade cable cleats. With a focus on quality and reliability, we offer a wide range of cable cleats designed to meet the diverse needs of our customers. Whether you require cleats for electrical power distribution, telecommunications, industrial applications, or other purposes, Dingdong Electrical has you covered. Trust us for top-quality cable cleats that ensure safety and reliability in your cable management systems. Please do not hesitate to contact us for more information about cable accessories.