HOME

/

What Is A Cable Marker Tag?

What Is A Cable Marker Tag?

What are Cable Marker Tags?

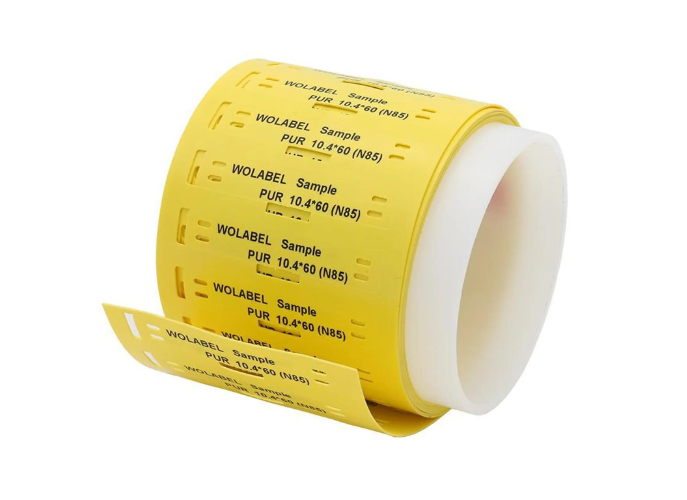

A cable marker tag is a small label or tag used to identify and organize cables, wires, and other electrical conductors. These tags are typically made from durable materials like plastic or metal and are designed to withstand various environmental conditions. They are available in different forms, such as pre-printed tags with standard labels, blank tags that can be customized with specific information, and specialized tags like wrap-around or clip-on types. The primary purpose of a cable marker tag is to provide a clear and legible means of identifying cables to ensure proper organization, maintenance, and safety in various applications.

Cable marker tags play a crucial role in numerous industries, including electrical engineering, telecommunications, industrial machinery, and construction. In the electrical and electronics industry, these tags are essential for labeling wires and cables in control panels, junction boxes, and other installations. Proper labeling helps in maintaining an organized system, making it easier for technicians to troubleshoot issues, perform maintenance, and ensure the safety of the system. It also reduces the risk of accidental disconnections or incorrect connections, which can lead to equipment failure or safety hazards.

In the telecommunications industry, cable marker tags are vital for managing and identifying the myriad of network cables that connect various devices and systems. With the increasing complexity of modern telecommunications infrastructure, clear labeling is essential for efficient network management and troubleshooting. Properly labeled cables ensure that any network issues can be quickly identified and resolved, minimizing downtime and maintaining the reliability of communication systems.

Industrial machinery and automation systems also benefit significantly from the use of cable marker tags. These environments often involve a large number of control cables and hoses that need to be clearly identified to ensure smooth operation. Properly marked cables help in quick identification during maintenance or in case of a malfunction, thereby enhancing operational efficiency and reducing downtime. In construction, cable marker tags are used to manage electrical installations and ensure compliance with regulatory standards. They help in keeping track of the numerous electrical connections within a building, making it easier for electricians to follow the wiring plan and perform inspections.

Types of Cable Marker Tags

1. Pre-printed Cable Marker Tags

Pre-printed cable marker tags come with pre-defined labels, symbols, or numbers already printed on them. These tags are typically made from durable materials like PVC or polyester, ensuring they can withstand various environmental conditions. The pre-printed information is usually standardized, making these tags ideal for quick and consistent identification of cables and wires without the need for additional labeling equipment.

Common Uses

Pre-printed cable marker tags are commonly used in environments where certain cable identifiers are frequently required, such as data centers, electrical panels, and industrial settings. They are particularly useful for labeling standard connections, voltage ratings, or specific functions like ground, neutral, or phase conductors. Their use simplifies the labeling process, reduces errors, and ensures uniformity across different installations.

2. Blank Cable Marker Tags

Blank cable marker tags are versatile labeling solutions that come without any pre-printed information, allowing users to customize the tags according to their specific needs. These tags are typically made from materials like nylon or vinyl and can be written on using permanent markers, printed using thermal transfer printers, or embossed with specialized equipment.

Methods of Customization

Customization of blank cable marker tags can be achieved through various methods. Handwriting with permanent markers offers a quick and flexible solution for on-site labeling. For more durable and professional labeling, thermal transfer printers can print text, barcodes, or graphics onto the tags. Embossing provides a permanent and tamper-resistant option, ideal for harsh environments where the labels need to withstand extreme conditions.

3. Wrap-around Cable Marker Tags

Wrap-around cable marker tags are designed to encircle the cable, providing 360-degree visibility of the label. These tags are often made from flexible materials such as vinyl or polyester, which allow them to conform to the shape of the cable. The design typically includes a clear section that overlays the printed information, protecting it from dirt and abrasion.

Advantages

The main advantage of wrap-around cable marker tags is their visibility from any angle, which is particularly useful in densely packed or confined spaces. The protective overlay ensures the printed information remains legible even in harsh environments, making them ideal for outdoor or industrial applications. Additionally, their flexible nature allows them to be used on cables of various diameters.

4. Clip-on Cable Marker Tags

Clip-on cable marker tags are small, rigid tags that attach to cables using a clip mechanism. These tags are usually made from durable plastics such as polypropylene or polycarbonate and can be easily attached and removed without the need for tools. The clip design ensures that the tags stay securely in place even in environments with significant vibration or movement.

Applications

Clip-on cable marker tags are commonly used in situations where cables need to be frequently re-labeled or reorganized, such as in telecommunications or IT data centers. Their ease of attachment and removal makes them ideal for temporary installations or when the labeling needs to be updated regularly. They are also useful in environments where adhesive-based tags might fail due to high temperatures or moisture.

5. Heat Shrink Cable Marker Tags

Heat shrink cable marker tags are made from heat-shrinkable tubing that shrinks tightly around a cable when heated. These tags are usually printed with information before application, and the shrinking process ensures the label conforms closely to the cable’s surface. Heat shrink tags provide a permanent and tamper-evident labeling solution.

Benefits

The primary benefit of heat shrink cable marker tags is their durability and permanence. Once shrunk, these tags are resistant to abrasion, chemicals, and extreme temperatures, making them ideal for demanding environments such as aerospace, military, and industrial applications. They also provide a neat and professional appearance, ensuring that the labeling remains intact and legible over the lifetime of the cable.

Materials Used in Cable Marker Tags

1. Plastic

Types of Plastic (PVC, Nylon, etc.)

Plastic is a common material used for cable marker tags due to its versatility and cost-effectiveness. Different types of plastic are employed depending on the specific requirements of the application. PVC (Polyvinyl Chloride) is widely used for its durability and ease of printing. It provides good resistance to moisture and chemicals, making it suitable for a variety of environments. Nylon is another popular choice, known for its high tensile strength and resistance to abrasion. Nylon tags are flexible and can withstand harsh conditions, including exposure to oils and solvents.

Durability and Flexibility

Plastic cable marker tags offer a balance of durability and flexibility, which is essential for applications where tags need to conform to the shape of the cables and endure environmental stresses. PVC tags, for example, can be used in both indoor and outdoor settings, as they resist UV radiation and weathering. Nylon tags, with their superior mechanical properties, are ideal for more demanding industrial environments where physical wear and tear are significant. The flexibility of plastic tags ensures they can be easily applied to cables of various diameters without cracking or breaking.

2. Metal

Types of Metal (Stainless Steel, Aluminum, etc.)

Metal cable marker tags are chosen for applications that require high durability and resistance to extreme conditions. Stainless steel is a common material due to its excellent corrosion resistance, strength, and longevity. It can withstand harsh environments, including those with high humidity, saltwater exposure, and chemicals. Aluminum is another frequently used metal, valued for its lightweight and resistance to corrosion. It is also highly conductive and reflective, making it suitable for specific applications.

Use Cases and Longevity

Metal cable marker tags are typically used in environments where plastic tags would not be durable enough. This includes industries such as oil and gas, marine, aerospace, and heavy manufacturing. Stainless steel tags are particularly favored in these settings because they can endure extreme temperatures, mechanical stress, and chemical exposure without degrading. Aluminum tags, while not as strong as stainless steel, are still used in many industrial applications where weight is a concern and corrosion resistance is necessary. The longevity of metal tags ensures that once applied, they provide reliable identification for the lifetime of the cable, reducing the need for frequent replacements.

3. Heat-resistant Materials

Importance in High-temperature Environments

Heat-resistant materials are crucial for cable marker tags used in high-temperature environments where conventional plastic or metal tags might fail. These materials, which include certain high-performance plastics and specially treated metals, are designed to withstand temperatures far beyond what standard materials can handle. For instance, materials like PTFE (Polytetrafluoroethylene) and silicone can endure continuous exposure to temperatures above 200°C without losing their properties.

In environments such as power plants, aerospace, and industrial ovens, the use of heat-resistant cable marker tags ensures that identification remains intact even under extreme heat. This is critical for safety, maintenance, and operational efficiency, as it prevents the degradation of tags that could lead to misidentification or loss of crucial information. Heat-resistant tags ensure that cables can be accurately identified and traced, supporting the reliability and safety of high-temperature operations.

Applications of Cable Marker Tags

1. Electrical and Electronics Industry

Labeling Wires and Cables in Control Panels

In the electrical and electronics industry, cable marker tags are indispensable for labeling wires and cables within control panels. These panels often contain a dense array of wires connected to various components and terminals. Proper labeling with cable marker tags ensures that each wire can be quickly and accurately identified, which is crucial during the installation, maintenance, and troubleshooting of electrical systems. By using pre-printed or customizable tags, technicians can efficiently organize and manage the numerous connections within a control panel.

Importance in Safety and Maintenance

The importance of cable marker tags in safety and maintenance cannot be overstated. Clear and accurate labeling helps prevent errors that could lead to equipment failure, electrical shorts, or even fires. During maintenance, technicians rely on these labels to safely disconnect and reconnect wires, ensuring that the system operates correctly and safely. Additionally, in emergency situations, having well-labeled cables allows for quicker response times in isolating and resolving issues, thereby enhancing the overall safety and reliability of electrical installations.

2. Telecommunications

Organizing and Identifying Network Cables

In the telecommunications industry, the organization and identification of network cables are critical due to the sheer volume and complexity of connections. Cable marker tags help technicians manage the extensive cabling infrastructure, from data centers to individual workstations. Proper labeling ensures that each cable can be traced from end to end, facilitating efficient network management and minimizing the risk of errors during installation or modifications.

Ensuring Efficient Troubleshooting

When network issues arise, having a well-labeled cabling system is essential for efficient troubleshooting. Cable marker tags enable technicians to quickly locate and identify specific cables, reducing the time needed to diagnose and fix problems. This efficiency is particularly important in large-scale telecommunications environments, where downtime can be costly and disruptive. By ensuring that all cables are properly labeled, telecommunications companies can maintain high levels of service reliability and customer satisfaction.

3. Industrial Machinery

Identifying Control Cables and Hoses

In industrial settings, machinery often relies on a complex network of control cables and hoses to operate various components. Cable marker tags are crucial for identifying these connections, ensuring that each cable or hose is correctly routed and connected. This identification is essential during both the initial setup and subsequent maintenance of the machinery.

Enhancing Operational Efficiency

The use of cable marker tags in industrial machinery enhances operational efficiency by reducing downtime and improving maintenance processes. When each cable and hose is clearly labeled, technicians can quickly identify and address issues, perform routine maintenance, and make necessary adjustments without confusion or delay. This efficiency translates to increased productivity and reduced operational costs, as machines can be kept running smoothly and safely.

4. Construction

Managing Electrical Installations

In the construction industry, managing electrical installations involves coordinating numerous wires and cables throughout a building. Cable marker tags help electricians organize and label these connections according to the electrical plan, ensuring that each wire is correctly identified and routed. This organization is vital for both the construction phase and future maintenance work, as it simplifies the identification and troubleshooting of electrical circuits.

Role in Regulatory Compliance

Cable marker tags play a significant role in ensuring regulatory compliance in construction projects. Building codes and safety regulations often require that electrical systems are clearly labeled to facilitate inspections and ensure safety. By using standardized cable marker tags, construction professionals can meet these requirements, avoiding potential fines and ensuring that the building’s electrical system is safe and up to code. This compliance is not only a legal necessity but also a critical aspect of delivering high-quality, safe construction projects.

Methods of Installing Cable Marker Tags

1. Manual Installation

Tools Required

Manual installation of cable marker tags typically requires basic tools such as permanent markers, cable ties, or adhesive labels. Depending on the type of cable marker tag and the application, additional tools like scissors or wire cutters may also be necessary.

Step-by-Step Process

Prepare the Cable: Ensure that the cable or wire to be labeled is clean and free of any debris or grease.

Select the Tag: Choose the appropriate cable marker tag for the application, whether pre-printed, blank, wrap-around, or clip-on.

Write or Print Information: If using blank tags, write or print the necessary information onto the tag using a permanent marker or thermal transfer printer.

Apply the Tag: Depending on the type of tag, affix it to the cable using adhesive backing, cable ties, or by wrapping it around the cable.

Secure the Tag: Ensure that the tag is securely attached and positioned in a visible location for easy identification.

Repeat as Needed: Continue the process for each cable or wire that requires labeling, ensuring consistency and accuracy throughout the installation.

2. Automated Installation

Equipment Used

Automated installation of cable marker tags typically involves specialized equipment designed for high-speed and precision labeling. This equipment may include:

Label Printers: Automated label printers capable of printing large quantities of cable marker tags quickly and accurately.

Label Applicators: Machinery equipped with mechanisms for automatically applying pre-printed or custom-printed tags to cables with minimal manual intervention.

Barcode Scanners or RFID Readers: Devices used for reading and encoding information on cable marker tags, facilitating inventory management and traceability.

Benefits in Large-Scale Applications

Efficiency: Automated installation significantly reduces the time and labor required for labeling cables, especially in large-scale applications such as data centers, manufacturing facilities, or telecommunications infrastructure.

Consistency: Automated systems ensure consistent labeling quality and placement, minimizing the risk of errors or inconsistencies that can occur with manual installation.

Cost-Effectiveness: While initial investment in automated equipment may be higher, the long-term cost savings in labor and increased productivity make it a cost-effective solution for large-scale installations.

Traceability: Automated systems often include features such as barcode or RFID encoding, enabling accurate tracking and traceability of cables throughout their lifecycle, from installation to maintenance and beyond.

Scalability: Automated systems can easily scale to accommodate growing or changing labeling needs, making them suitable for environments with evolving infrastructure requirements.

Advantages of Using Cable Marker Tags

1. Improved Organization

One of the primary advantages of using cable marker tags is the significant improvement in organization. In any environment where numerous cables and wires are present, such as data centers, industrial facilities, or construction sites, keeping cables neatly organized can be challenging. Cable marker tags provide a systematic way to label each cable, making it easier to identify and manage connections. This organized approach not only streamlines installation processes but also ensures that cables can be easily traced and followed, reducing the risk of confusion and errors. As a result, well-organized cable systems enhance overall efficiency and productivity.

2. Enhanced Safety

Enhanced safety is another critical benefit of using cable marker tags. In electrical and industrial settings, improper handling or misidentification of cables can lead to serious accidents, including electrical shocks, short circuits, or fires. By clearly labeling each cable with relevant information, such as voltage ratings, functions, or warning signs, cable marker tags help prevent accidental disconnections and incorrect connections. This clear labeling ensures that technicians and workers can safely perform their tasks, significantly reducing the risk of accidents and ensuring a safer working environment.

3. Easier Maintenance and Troubleshooting

Cable marker tags play a crucial role in simplifying maintenance and troubleshooting tasks. When cables are clearly labeled, technicians can quickly identify the specific cables that need attention, whether for routine maintenance or when addressing a malfunction. This ease of identification reduces the time required to locate and isolate issues, leading to faster repairs and less downtime. Additionally, well-labeled cables facilitate easier documentation and record-keeping, as maintenance logs can accurately reference specific cables and their conditions. Overall, cable marker tags make the maintenance process more efficient and less prone to errors.

4. Compliance with Standards and Regulations

In many industries, compliance with standards and regulations is essential to ensure safety and reliability. Cable marker tags help businesses meet these regulatory requirements by providing a standardized method of labeling and identifying cables. Various industry standards, such as those set by the National Electrical Code (NEC) or International Electrotechnical Commission (IEC), often mandate specific labeling practices to ensure safety and consistency. By using compliant cable marker tags, businesses can avoid potential fines and legal issues while ensuring that their installations meet the required safety and quality standards. This compliance not only protects the organization but also enhances the credibility and reliability of its operations.

Choosing the Right Cable Marker Tag

1. Factors to Consider

Environment (Indoor, Outdoor, High Temperature, etc.)

The environment in which the cable marker tags will be used is a crucial factor to consider. Different environments present varying challenges, such as exposure to moisture, UV radiation, extreme temperatures, or chemicals. For outdoor applications, tags made from UV-resistant materials like polyester or nylon are recommended to withstand prolonged exposure to sunlight. In high-temperature environments, heat-resistant materials such as heat shrink tubing or specialized plastics like PTFE are necessary to prevent degradation.

Durability Requirements

Consider the level of durability required for the cable marker tags based on the application. Tags used in harsh industrial environments or outdoor settings may need to withstand physical abrasion, chemicals, or mechanical stress. In such cases, durable materials like stainless steel or rugged plastics are preferred. For less demanding environments, standard plastic tags may suffice, provided they offer adequate resistance to wear and tear.

Size and Type of Cables

The size and type of cables being labeled will influence the choice of cable marker tags. Tags must be appropriately sized to fit the diameter of the cables without being too loose or too tight. Additionally, consider the flexibility of the tags, especially when labeling cables with irregular shapes or bends. For smaller cables, thinner and more flexible tags are preferable to ensure a secure fit without adding bulk.

2. Recommendations Based on Industry Needs

Based on specific industry needs, here are some recommendations for choosing the right cable marker tags:

Electrical and Electronics Industry: In this industry, where safety and compliance are paramount, durable and legible cable marker tags are essential. Pre-printed or customizable plastic tags with high-contrast printing are suitable for labeling wires and cables in control panels and junction boxes.

Telecommunications: Given the complex and often densely packed nature of telecommunications infrastructure, cable marker tags with clear and concise labeling are crucial. Wrap-around or clip-on tags made from flexible materials like vinyl or polyester are recommended for organizing and identifying network cables.

Industrial Machinery: In industrial environments with heavy machinery and equipment, cable marker tags must withstand rugged conditions. Metal tags made from stainless steel or aluminum provide durability and resistance to corrosion, making them ideal for identifying control cables and hoses.

Construction: In construction projects, compliance with building codes and safety regulations is essential. Heat shrink cable marker tags offer permanent and tamper-resistant labeling solutions that meet regulatory requirements. These tags are particularly useful for managing electrical installations and ensuring safety and compliance on construction sites.

Conclusion

In conclusion, cable marker tags are indispensable tools in modern cable management, offering numerous advantages across various industries. Their primary function is to provide clear and legible identification for cables, significantly improving organization and ensuring that complex systems remain manageable. This enhanced organization not only streamlines installation processes but also facilitates efficient maintenance and troubleshooting, reducing downtime and operational costs.

The use of cable marker tags greatly enhances safety by preventing misidentification and accidental disconnections, which can lead to severe accidents or equipment failures. By clearly labeling each cable with relevant information, these tags ensure that technicians and workers can perform their tasks safely and efficiently. Additionally, the durability and adaptability of cable marker tags make them suitable for a wide range of environments, from indoor control panels to harsh industrial settings and high-temperature applications.

Furthermore, cable marker tags play a crucial role in ensuring compliance with industry standards and regulations. By adhering to mandated labeling practices, businesses can avoid legal issues and fines while maintaining high safety and quality standards. This compliance not only protects the organization but also boosts its credibility and reliability.

In essence, choosing the right cable marker tags, considering factors such as environmental conditions, durability, and specific industry needs, can greatly enhance the efficiency and safety of cable management systems. Whether in the electrical and electronics industry, telecommunications, industrial machinery, or construction, cable marker tags are essential for maintaining order, safety, and compliance in increasingly complex and demanding environments.